Look beneath the surface and you’ll see all that CMC offers — Strength. Integrity. Dependability. That’s not just a description of our products, but our people. CMC’s Early-Stage Construction solutions support smarter planning, better site preparation, and stronger foundations at the heart of modern infrastructure — from AT&T Stadium in Dallas to the Pentagon to essential highways, bridges and buildings all over the world.

But at CMC, we also work hard to build something far more important — lasting relationships. The kind of partnerships that keep our customers returning to us time and again for their most important and challenging projects. Such loyalty is driven by the passion of our people. Such loyalty doesn’t happen by chance or convenience. It’s the result of the passion of our people. At CMC, we care about the products we make, the folks we make them for, and the world we all share — now and for generations to come.

what we do

Forward Thinking

T-Post Automation

CMC currently operates the most automated T-post fabrication facility in the world.

Learn MoreNet Zero Steel

In 2022, CMC launched its Zero line, providing customers with a carbon-neutral steel solution.

Learn MoreMini Mill

Every CMC mill uses electric energy and 100% recycled scrap to produce our products.

Learn MoreSlitting Process

CMC was the first in the industry to successfully complete a three and five slit process.

Learn MoreMicro Mill

CMC was the first in the world to successfully operate a highly energy-efficient micro mill.

Learn Moremy CMC

CMC was the first steel company in the U.S. to build and release an online customer portal.

Learn MoreTrucking Fleet

CMC has its own trucking fleet dedicated to meeting our customers’ needs.

Learn MoreSpooled Rebar

CMC became the first producer of spooled rebar in the U.S.

Learn More

WE USE 100% RECYCLED STEEL

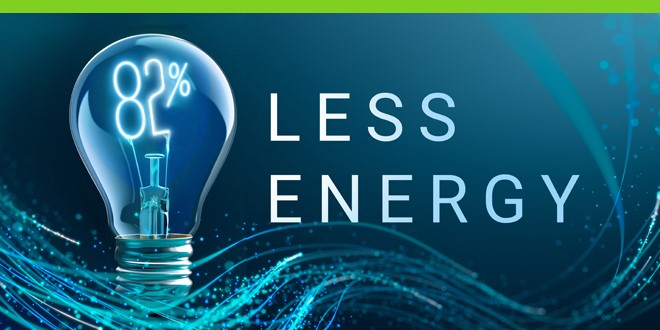

We use 82% less energy than traditional steelmaking

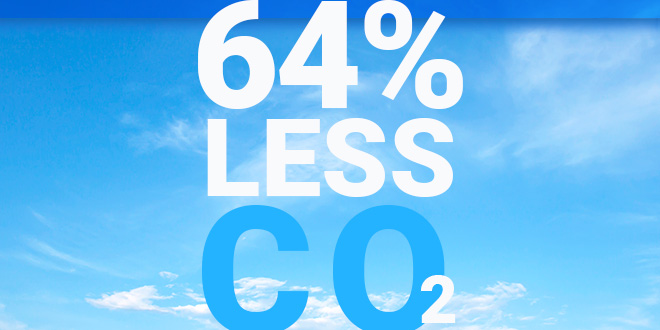

We produce 64% less CO2 per ton of steel

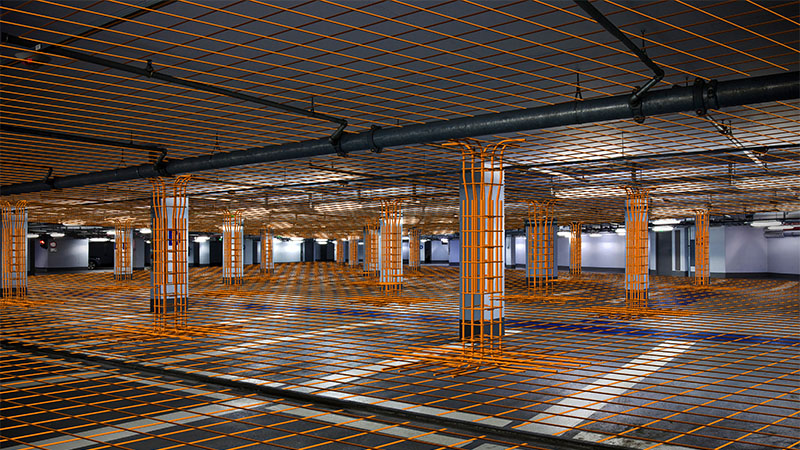

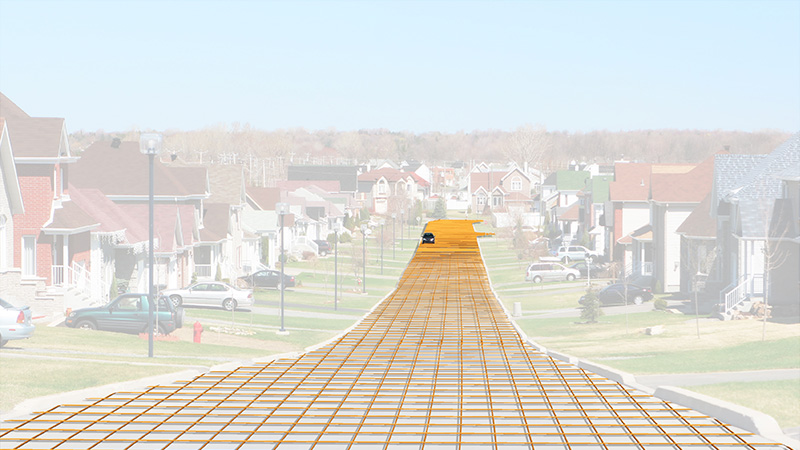

x-ray vision

see what's inside

CMC steel serves as the backbone for an incredible array of highways, structures and other projects. It’s just not always obvious. That’s why we’ve created this easy way for you to look inside and see the strength and versatility of CMC steel for yourself.